Quality Control

How do we do the quality control ?

The Nail Polish Containers are made of soda-lime glass, complying with the green environmental protection label, no environmental pollution, recyclable, and the content of lead and cadmium meet the US FDA standards. All Raw Materials used in the nail polish bottles are compliant with SGS certificates. GH Plastic will check the products such as glass bottles, plastic caps and brushes prior to shipping, the final products will not be shipped out until inspector has done the checking list.

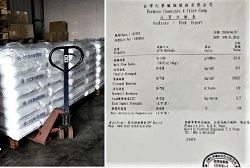

Nail Polish Glass Bottles, Caps, and Brushes are packed separately in the cartons and all the cartons are packed on the pallets for shipping safety.

We offer extra quantity of nail polish bottles, caps, and brushes as spare parts in each shipment. The extra quantities are for replacement in case any damaged or broken bottles caused during transportation.

Nail Polish Bottles, Caps, and Brushes QC Flow Chart

Incoming Check of Raw Material of Nail Polish Plastic Cap

PP or PE suppliers will provide the test report for each batch of incoming raw materials.

Nail Polish Plastic Caps Checking on Production

The nail polish plastic caps are produced by automatic injection machine equipped with computer and auto arm. All the production parameters are set by the computer. We check the nail polish caps on the conveyor after the auto arm picked up the plastic caps from the mold and placed them on the conveyor. The NG caps will be returned to the mixer for re-production. The qualified nail polish caps are going down to the basket slowly to avoid scratch among the nail polish plastic caps before packaging.

Nail Polish Plastic Caps Packaging Checking

The qualified nail polish caps are put in the polybag in the basket for packaging. 500 pcs of nail polish caps are packed in a polybag and 8 or 10 bags are in a carton, after bags are weighed and sealed. The product label with part number, quantity, and production date will be put on each carton.

Assembled Nail Polish Plastic Caps and Brushes

We can fit the brush into the plastic cap by tool machine for the customer (optional). The attached nail polish caps and brushes are placed on trays after visual inspection.

Nail Polish Brush Checking

The nail polish brushes are produced by automatic machine. All the production parameters are set by the computer. The nail polish brushes are visual inspected on the baskets or trays. 1000 pcs of nail polish brushes are packed in a polybag and 10 or 15 bags are packed in a carton, after bags are weighed and sealed. The product label with part number, quantity, and production date will be put on each carton.

Nail Polish Glass Bottles Checking on Production Process

The Nail Polish Glass Bottles are produced by the molds on automatic machines. All the production parameters are set by the computer. The nail polish glass bottles are visual inspected on process, before packed in the carton with partitions. The COA report of nail polish glass bottles will be provided by the glass factory, and we will inspect the nail polish glass bottles again before shipment.

Checking the dimensions of Gel Nail Polish Glass Bottles by Meter

We use Mitutoyo digital meter to check the dimensions of glass bottles (width, length, deepth, height, diameter, and neck size, etc.) to make sure the perfect shape of the bottles before shipment.

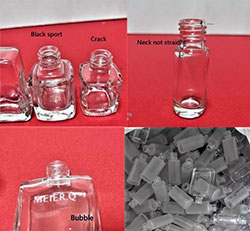

NG Nail Polish Glass Bottles

We sort out the NG bottles such as bottles with black spot, crack, bubble, scratch line on bottle surface, bottle neck not straight, or bottles with burr, etc. We put the NG bottles in the bag and send them back to the glass factories.